Artificial Intelligence

Industry Standards

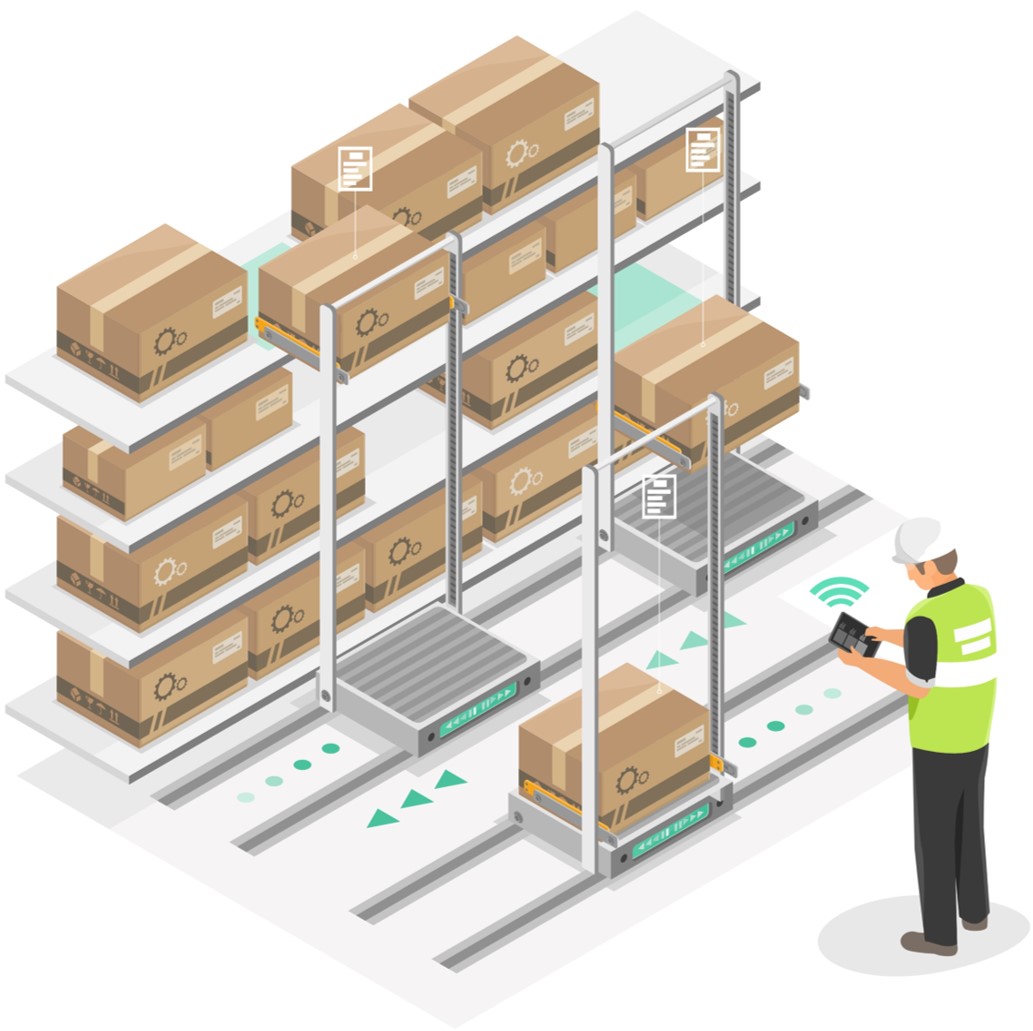

With the aid of cutting-edge technology enablers, fruiSCE® Warehouse Management is a comprehensive solution to manage all the major warehousing challenges. With the use of artificial intelligence and IoT device integration, it offers total control, administration, and visibility of warehouse operations. All types of warehouse operations, including distribution centres, 3PL, manufacturing, and retail, can be carried out seamlessly.

The autonomy and independence of fruiSCE® WMS assures that it can meet the demands of order processing, warehousing, and distribution requirements. The benefits of adopting fruiSCE® WMS include the possibility to deploy it on-premises, in the cloud, or a hybrid deployment model, industry-specific capabilities, and multisite warehousing.

Industry Standards

Industry Standards

Industry Standards

Generate purchase orders for several line items with various pricing and structures. Easily insert large purchase orders using the excel upload feature, or automatically transfer purchase orders from ERP.

Goods Receipt Notice can be created manually or automatically after receiving ASN or EDI. By a bill of lading receipt, partial or full quantities may be received. Simple goods receipts are possible with mobile application.

Based on putaway principles that provide optimal space use, automatic putaway is advised. Putaway can be carried out quickly and accurately using an RF gun or a mobile application after the quality check.

The operations can be coordinated to allow for cross docking depending on the type of deliveries and reception. Various types of cross-docking can be controlled with the help of delivery order triggers, direct shipment transfers, temporary storage, or partial transfers.

Inventory transfers between locations and inventory changes can be used to eliminate any discrepancies. To maintain inventory accuracy and make regular adjustments for accurate inventory visibility, cycle counting and physical inventory are helpful.

Based on industry best practises, sales orders are generated either automatically or manually for product delivery. Using an ERP or another system, the sales orders can be transferred. Excel upload functionality is used to upload sales orders in bulk.

The process supports all necessary phases, including tram management, empties, and other forms of picking processes, when goods are provided for manufacturing. It is possible to control all raw material use and end product receipts.

Using a variety of picking optimization logics, automated picking is accomplished through optimised picking processes. On the basis of the picking and dispatching procedure, necessary advanced shipment notices can be sent.

With provisions for a number of accounting reports, the accounting will be settled for inbound and outbound invoicing as well as to register expenses. It is possible to bill for sales deliveries.

Gate-in and gate-out procedures can be used to create time stamps and registration data to assist warehouse security procedures. The necessary paperwork and data can be registered and connected to the receipt or delivery of products.

With e-commerce platforms, the order drop can be carried out automatically at predetermined intervals or in response to trigger inputs. Using e-commerce connectivity, purchase orders or/and sales orders can be generated automatically.

ASNs can be obtained from suppliers, and capacity management is also possible. The trigger mechanism can be used to deliver the ASNs for departing shipments. Via the ASN mechanism, necessary capacity management can be carried out.

The item's size can be registered for length, breadth, and depth when creating GRNs. Calculating volumetric numbers and capacity planning for volume both benefit from this information. Based on the cubing method, the bin spaces and location size can be estimated.

All possible billing methods are available to have the warehousing costs calculated. Billing purchase order and billing invoice can be made for the warehouse customers. Users can switch the billing methods at ease and the costs incurred are calculated effortlessly.

Consulting for introducing best practices in Warehouse Management which include defining, layouts,, cubing, putaway and picking strategies, ASN, EDI, cross docking, inventory management, warehouse operations, capacity planning, and performance management.

Implement Warehouse Management process which include, purchasing, putaway, cross docking, picking & shipping, sales orders, invoicing, bulk pick and each pick locations, cycle counting, inventory transfers and adjustments, and master data definition.

Integration with all complementing solutions and data sources which include ERP, TMS, barcoding, RFID, QR codes, eCommerce portals, equipment, through OPC UA protocol and others to have seamless flow of data to make data available on time to enable better decision making.

Software solution which is comprehensive, easy to implement, easy to maintain, built on latest technology stack, empowered by AI/ML, process mining, mobility, API enabled, Cloud empowered, and with great user interface.

fruiSCE® WMS is designed to cater services to various industries and the following are a few of them.

© 2023 - Data Labs America all rights reserved.