Artificial Intelligence

Industry Standards

SAP S/4HANA is one of the largest enterprise solution suite brands globally. It comes with a strong reputation and pedigree, modern & future-ready architecture, rich functionally, easy deployment, configuration and a clear upgrade roadmap from SAP ECC/R/3. As the ‘digital core’ of organizations, it helps them successfully transform their business, drive simplification, enable real-time data for rapid decision-making, and deliver tangible business value.

As organizations prepare themselves to address their competitive landscape, we assist them in reimagining and re-engineering their business. DLI SAP S/4HANA CoE has developed industry best practices, frameworks, and repositories to help SAP customers seamlessly deploy SAP S/4 HANA (On-premise/ Cloud).

Industry Standards

Industry Standards

Industry Standards

Introduce SAP S/4 HANA and digitize your core to become a digital enterprise. Simplify your data model and create a single source of truth for better insights in real-time.

Bring together data visualization, planning, and predictive capabilities all on your own without the help of a data scientist with advanced embedded analytics and graphical representation.

Create role-based custom applications with modern design principles while our UI experts provide a centralized view of technology, processes, and products for enhanced customer experience.

Level up warehouse performance and management with advanced features like enhanced production processes, material flow system, automatic storage and retrieval system, etc.

Leverage continuous monitoring, effective decision-making, real-time visibility, and GRC process integration to streamline operations and safeguard critical business processes.

Streamline and centralize the finance function and automate all traditional financial tasks transforming to intelligent finance without disturbing the existing functionalities.

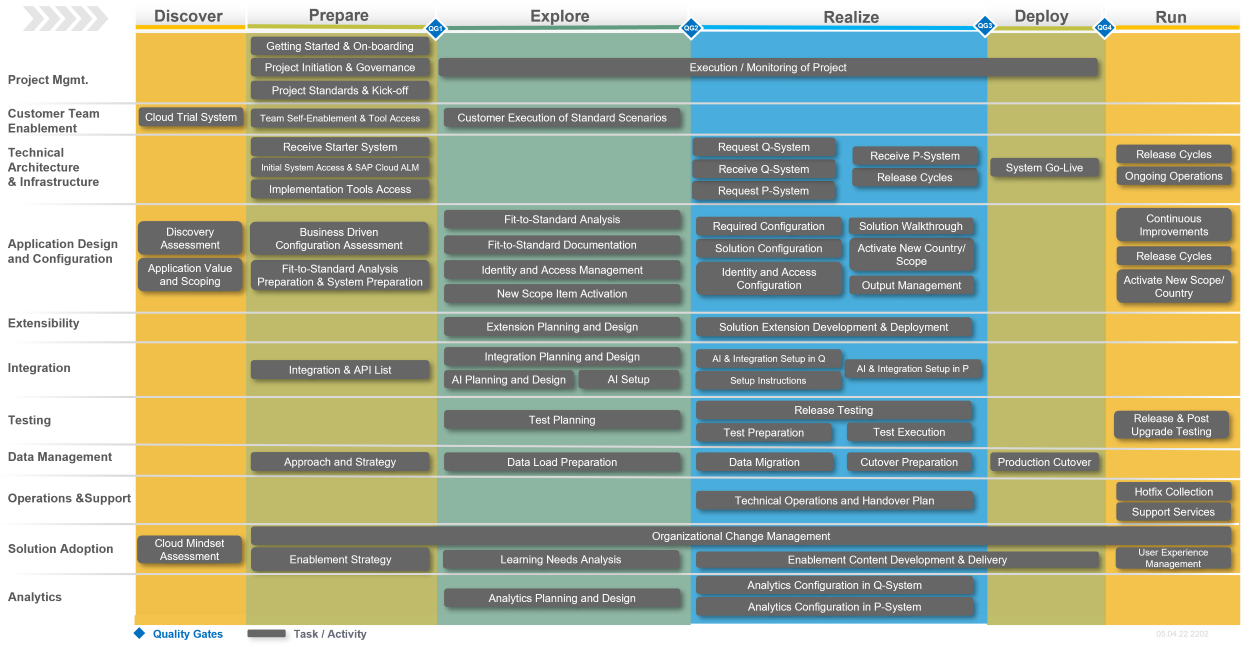

During this phase strategic planning of the project, application value and scoping is defined by provisioning trial systems.

The entire design of the project is done in this phase along with understanding the impact of the operations at every stage.

Once the operational readiness of the project is tested, it will be deployed under Hyper Care.

Initiation of the project, team enablement, transition planning and preparation is carried out while prototypes of the project are built.

The completed design needs to be developed, executed, and data has to be migrated. Testing is done once the afore said tasks are complete.

The completed project is handedover to the organization after successful implementation. Innovation and Improvements can be done as needed

Consulting for introducing best practices in Manufacturing Management which include defining, digital twin, work centers, machines, operations, performance reporting, order management, energy management, tooling, maintenance, planning and scheduling.

Implement the Manufacturing Execution process which includes, production orders, work centre reporting, material balancing, energy planning, integration with machines, performance analytics, production scheduling, MRP and MPS, and OEE reporting.

Integration with all complementing solutions and data sources which include ERP, Excel, LoB solutions, Machines, through OPC UA protocol and others to have a seamless flow of data to make data available on time to enable better decision making.

Software solution which is comprehensive, easy to implement, easy to maintain, built on the latest technology stack, empowered by AI/ML models, process mining, mobility, API enabled, Cloud empowered, and with great user experience.

© 2023 - Data Labs America all rights reserved.